- Nuclear Reactors, Boilers, Machinery And Mechanical Appliances; Parts Thereof

- Moulding Boxes For Metal Foundry; Mould Bases; Moulding Patterns; Moulds For Metal (other Than Ingot Moulds), Metal Carbides, Glass, Mineral Materials, Rubber Or Plastics.

- Moulds For Metal Or Metal Carbides (excl. Moulds Of Graphite Or Other Carbons, Ceramic Or Glass Moulds, Linotype Moulds Or Matrices, Injection Or Compression-type Moulds And Ingot Moulds)

Plastic injection chrome side mirror cover mould

Product Images

Product Property

| Shaping Mode : | Plastic Injection Mould |

| Product Material : | steel |

| Design Software : | UG,PROE,CAD |

| machine : | CNC,EDM,Drilling,Milling |

| Mould base : | LKM,HASCO,DME |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob |

| Payment Mode : |

T/T,L/C,cash,PayPal,MoneyGram |

Description

We can make different types of chrome mirror cover mould according to clients'requirement. The quotation is made base on samples or drawings provided by clients. Our mirror cover moulds are both excellent in quality and competitive in price.

Your satisfaction is our aim.

Specifications

| Name | Description |

| Mould Name | Plastic injection chrome side mirror cover mould |

| Design Drawings | 3D/2D |

| Design Sofeware | UG, PROE, Solidworks, CAD…etc. |

| Plastic Material | PP, PC, PE, PVC, ABS, POM, PMMA…etc.(for ref.) |

| Mould Shaping | Injection Mould |

| Demould Type | Automatic Eject |

| Steel of Cavity & Core | P20, 718, 738, 2738, NAK80, SKD61…(for ref.) |

| Steel of Mould Base | LKM/HASCO/LOCAL/DME…etc.(for ref.) |

| No. of Cavity | Multi |

| Mould Accessories | DME/HASCO/PUNCH/JINHONG…etc.(for ref.) |

| Surface Finish | Logo print, Texture, Polish, ... |

| Precision Machining | CNC/Wire Cutting/Carved/EDM/Milling/Grinding/Drilling, etc. |

| Mould Life | 300, 000-1, 000, 000 Shots |

| Runner | Hot/Cold |

| Delivery Time | 2-7 weeks upon receipt of order |

| Packing | Plywood Case or Customized |

| Transportation | By Sea, etc. |

| Sales Market | Global |

Packaging:

1. Plywood Case

Or as per customer requirements

Shipping:

By Air: FedEx, DHL, UPS, TNT, etc.

Or By Sea

Our Services

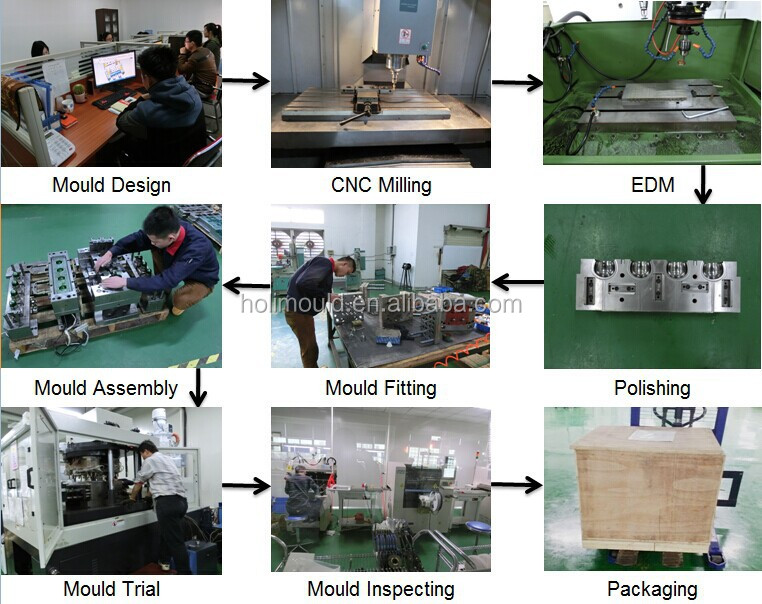

Mould Manufacture Flow Chart

Advantages of Holi Mould

| R&D ability | For injection mould, we have over ten years experience and form lots of professional technical persons and engineers. We focus on some key points like Best gate location, Filling time, Flow front temperature, Filling ends pressure, Sink mark index, Warpage Analysis, etc. Now we are able to deal with every hard problem to help our customers achieve their perfect products. |

| Precision | 1.We utilize ISO9001:2008 & TS16949 standards in our operation 2.CNC tolerance: +/-0.005mm 3.WC tolerance:+/-0.003mm 4.EDM Mirror tolerance:+/-0.003mm 5.Precise Grinding Machine:+/-0.001mm |

| Quality | Best QA & QC system can guarantee product quality. They inspect almost every mass production step from raw material arrival inspection, mould parts production process control, to moulds already assembled checking and testing, final production package inspection, etc. Besides, our salesman will also spot check these steps to ensure mass production quality. |

| Professional Team | 1.Our team has strong energy and capability to help you achieve your idea: design-production-surface treatment-assembly-package-shipment etc. 2.Skilled designer with related software (CAD, UG, PRO-E, Solidworks, Catia etc.) can draw your products. 3.Professional knowledge will solve every difficult problem. 4.With strong responsibility and good communication to reach high efficient and accurate work. 5.Excellent team work will meet your various requirements. |

Our mould products cover the following fields:

Auto parts, Lighting, Houseware, Electronics......

Company Information

FAQ

| Process of making moulds | |

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to R&D team to do moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send sample for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

| 9.Package | PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirement. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |